Ayurveda is one of the oldest recorded systems of medicine in the world, and its importance is increasingly felt in today’s preventive medicine segment. But to ensure that an Ayurvedic supplement works, it is not just dependent upon its traditional medicinal values but also upon how it is made.

Ayurvedic product manufacturing is a highly regulated and process-driven field that blends the traditional Ayurveda systems with contemporary quality management and scientific validation. For the brand marketers or the exporters, knowledge about this process from raw herb to the final product is very important when looking for the right partner for ayurvedic 3rd party manufacturing.

Understanding the Ayurvedic Product Manufacturing Journey

Ayurvedic product manufacturing requires accuracy, record-keeping,. Right from procurement to packaging, it aims to retain its preventive & therapeuticproperties along with safety.

Unlike traditional dietary supplements, “Ayurvedic” products need

- Genuine botanical procurement

- Formulation adherence

- Processing under GMP

- Multi-level quality testing

A professional Ayu Ayurvedic product manufacturing process guarantees the application of modern healthcare standards in the traditional treatments.

Foundations of Ayurvedic Product Manufacturing

The basis of Ayurvedic manufacturing is the authoritative classical texts like Charaka Samhita, Sushruta Samhita, and Ashtanga Hridaya, which define the constituents (ingredients), methods of preparation, dosage forms, and therapeutic use. Modern Ayurvedic product manufacturing, on the other hand, supplements this by:

- Qualified Ayurveda Physicians (BAMS)

- Ayurvedic pharmacists and formulation scientists

- GMP-certified manufacturing environments

- Standard Operating Procedures (SOPs) and Batch Documentation

This integration of traditional expertise with scientific manufacturing practices will be imperative for building long-term trust and regulatory credibility.

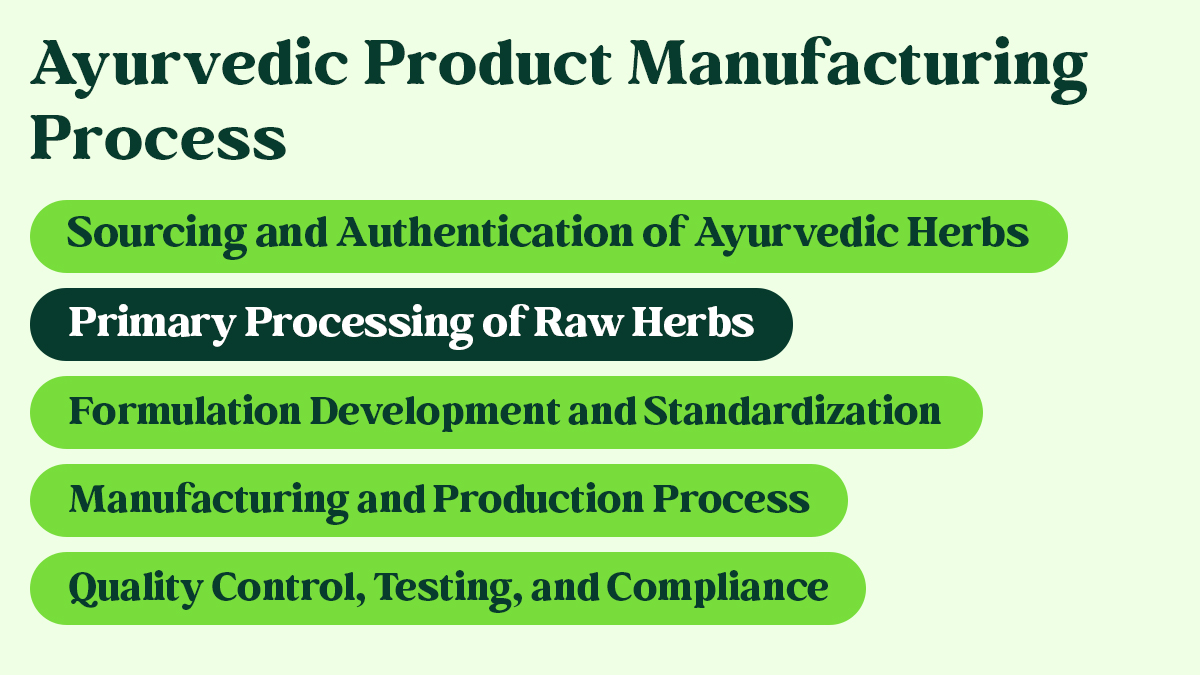

Ayurvedic Product Manufacturing Process

Due to this, a standardized manufacturing process is followed to ensure consistency among batches and adherence to various national and international regulations. The following is a step-by-step overview of how authentic Ayurvedic products are manufactured in professional facilities.

Step 1: Sourcing and Authentication of Ayurvedic Herbs

The manufacturing process is initiated by the careful selection of the raw materials.

- Herbs are sourced from approved suppliers.

- The identification by botanical means is done to confirm the genus, species, and part of the plant.

- Raw materials are tested for heavy metals, pesticide residues, microbial load, and adulterants.

Only authenticated and quality-approved herbs are released for further processing, thus ensuring safety and therapeutic reliability right from the first step of Ayurvedic product manufacturing.

Step 2: Primary Processing of Raw Herbs

For the medicinal herb to retain its strength, primary processing is very essential. This stage involves:

- Physical cleaning and the removal of impurities

- Controlled drying conditions of specific temperature and humidity

- Reduction of size through cutting, grinding, or pulverizing

- Storage in designated areas with environment monitoring

Step 3: Formulation Development and Standardization

The development of formulations is done by qualified Ayurvedic practitioners and R&D personnel.

- Classical formulations follow exact textual references

- In-house preparations are designed with specific goals of therapy in mind

- Standardization provides equivalent concentrations of active ingredients

In ayurvedic 3rd party manufacturing, this particular step enables companies to formulate products according to their own specifications, adhering to the principles of Ayurvedic norms.

Step 4: Manufacturing and Production Process

The production process occurs within GMP-approved facilities that are designed to avoid contamination. Important points include:

- Controlled production areas with standardized SOPs

- Equipment validation & process control

- Proper dosing and batch manufacturing record

- Preparation of Compound Preparations such as tablets, capsules, syrups, powders, oils, and topical preparations

It offers a systematic approach to facilitate scalability, consistency, and compliance for the entire process of Ayurvedic product manufacturing.

Step 5: Quality Control, Testing, and Compliance

Quality assurance is an integral part of any genuine production process of Ayurvedic medicines.

Each batch is exposed to:

- In-process quality checks

- Testing purity of finished products

- Microbiological Analysis and Heavy Metals Testing

Manufacturing units comply with GMP and national or international guidelines, which makes them audit-ready in terms of export as well as domestic markets.

Step 6: Packaging, Labeling, and Storage

Packaging and labeling receive the same attention of regulatory concern as manufacturing.

- Packaging materials are chosen to protect product stability.

- Labels are in compliance with statutory requirements.

- Batch numbers, expiry dates, and usage instructions should be clearly stated.

- Products are stored under controlled conditions prior to dispatch.

For brands opting for ayurvedic 3rd party manufacturing , private labeling, and packaging customization are offered while maintaining regulatory accuracy.

Role of Ayurvedic 3rd Party Manufacturing in Brand Growth

Professional third-party manufacturing in Ayurveda will definitely facilitate scaling up efficiently, with no compromises on either quality or compliance.

Key benefits include:

- Access to GMP-certified infrastructure

- Reduced capital & operational investment

- Quick product development and market entry

- Regulatory and documentary support

- Large-scale production with consistency in quality

Through outsourcing the production of their Ayurvedic products to an expert partner, companies can concentrate on marketing and expanding their business.

Conclusion

Genuine Ayurvedic products come from disciplined manufacturing processes, technically monitored, and completely uncompromising quality processes. The authentication of herbs right up to the final production is extremely important in Ayurvedic product manufacturing.

For trustworthy and compliance-oriented Ayurvedic third-party manufacturing, brands have to look for a competent manufacturer.

Aveda Ayur offers end-to-end Ayurvedic manufacturing solutions backed by GMP-certified facilities, qualified Ayurvedic professionals, robust quality control systems, and transparent regulatory practices. Whether you are launching a new Ayurvedic brand or scaling an existing portfolio, Aveda Ayur supports your journey with expertise, integrity, and manufacturing excellence.

Partner with Aveda Ayur in the creation of authentic, compliant Ayurveda products from conception to marketplace.

FAQs

-

How to select the right Ayurvedic 3rd party manufacturing partner for my brand?

Selecting the right partner within Ayurvedic third-party manufacturing requires evaluating GMP certification, compliance of the product with market regulations, use of quality ingredients, formulation expertise of the product, and manufacturing capacity. In addition to these factors, it is necessary that one look at the experience of the manufacturer in handling its own labels.

-

Does Ayurvedic Product Manufacturing offer customized and proprietary product formulations?

Yes, Professional Ayurvedic Product Manufacturing organizations support both conventional and proprietary formulas. Experienced manufacturers offer R&D assistance,, formulation standardization, and regulatory guidance to help brands launch differentiated products while maintaining compliance with Ayurvedic and statutory norms.

-

What is the average minimum order quantity for 3rd party ayurvedic manufacturing?

The MOQs differ depending on the form and complexity of the formulation. Flexible MOQ quotes are usually given to startups by reliable Ayurvedic 3rd-party manufacturing partners, while scalable production is offered to growing or established brands. Discussion on business objectives early on helps in optimization related to production and cost.

-

Is regulatory support and documentation offered by the vendor?

Known manufacturers of products with Ayurvedic origins offer complete regulatory support with respect to formulations of products, batch manufacturing records, and regulatory compliance for export markets. That’s precisely the kind of support that any brand would want to ensure seamless approvals and scalability in the long run.

-

Does Ayurvedic third-party manufacturing support export ready products?

Yes, experienced Ayurvedic 3rd party manufacturing partners design products that meet domestic and international quality standards, which include compliance with GMP, appropriate labeling, and documentation for global markets, thus allowing brands to expand confidently beyond India.